MCrAlY Alloy leh iska caabin heerkul sare ah

Sharaxaada

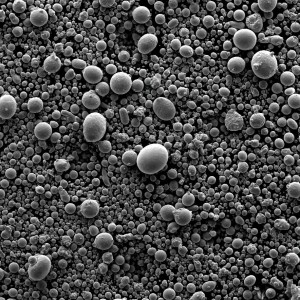

Summada:KF-301 KF-308 KF-309 KF-336 KF-337 KF-339… Nooca: Gaaska atomized

Guryaha budada:Halabuurka Kiimikada: MCrAlY (M = Fe, Ni, ama Co) Cabbirka Walxaha: -45 +15 µm Daahirnimada: ≥ 99.5%

Codsiga:Budada Alloy MCrAlY waxaa si weyn loogu isticmaalaa codsiyada heerkulka sare sababtoo ah sifooyinkooda gaarka ah.Waxa caadi ahaan loo isticmaalaa sida jaakadaha curaarta ee duubabka birta ah, duubabka saxanka kulul ee kulul, iyo duubabka daawaynta kulaylka.Intaa waxaa dheer, waxaa loo isticmaalaa warshadaha hawada sare si ay u soo saaraan qaybaha marawaxadaha gaaska, gaashaammada kulaylka, iyo daabka mishiinka hawada.

Astaamaha MCrAlY Alloy

1. Heerkulka Sare ee Resistance: MCrAlY Alloy budada waxay soo bandhigaan iska caabin heer sare ah oo heerkul sare ah.Gurigan waxa uu ka dhigayaa kuwo ku habboon in loo isticmaalo codsiyada kulaylka sarreeya sida marawaxadaha gaaska, foornooyinka daaweynta kulaylka, iyo duubabka birta ah.

2.Antioxidant Properties: MCrAlY Alloy budada waxay aad ugu adkaysanayaan oksaydhka heerkulka sare, taas oo ka dhigaysa mid ku haboon in loo isticmaalo jawi adag oo ay ku dhici karto oxidation, sida marawaxadaha gaaska iyo kulaylka.

3.Hot Corrosion Resistance: MCrAlY Alloy budada waxay soo bandhigaysaa caabbinta aad u fiican ee daxalka kulul, taasoo ka dhigaysa inay ku habboon yihiin isticmaalka codsiyada halka maaddadu ay soo bandhigto jawiga daxalka ah ee heerkulka sare.

4.Thermal Barrier Substrate: MCrAlY Alloy budada ah waxaa inta badan loo isticmaalaa sida substrates caqabad ku kulaylka sababtoo ah habdhaqanka kulaylka fiican iyo sifooyinka ballaarinta kulaylka.Waxaa loo isticmaalaa iyadoo lala kaashanayo dhoobada dhoobada si ay uga ilaaliso walxaha hoose ee jawiga heerkulka sare.

Guud ahaan, budada Alloy MCrAlY waa walxo kala duwan oo soo bandhigaya sifooyin heerkul sare oo heer sare ah, taas oo ka dhigaysa mid ku habboon in loo isticmaalo codsiyada kala duwan ee warshadaha kala duwan.Sifooyinkooda gaarka ah, oo ay ku jiraan iska caabbinta heerkulka sare, sifooyinka antioxidant, iska caabinta daxalka kulul, iyo guryaha xannibaadaha kuleylka, waxay ka dhigaan doorasho caan ah codsiyada heerkulka sare.

Alaabooyin la mid ah

| Summada | Magaca Alaabta | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-301 | ||||||

| KF-308 | NiCrAlY | 9621 | ||||

| KF-309 | NiCoCrAlY | |||||

| KF-336 | CoCrAlSiY | |||||

| KF-337 | CoNiCrAlY | 9954 | ||||

| KF-339 | CoCrAlYTaSiC |

Tilmaamid

| Summada | Magaca Alaabta | Kiimikada (wt%) | Adag | Heerkulka | Guryaha & Codsiga | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Al | Y | Ta | Si | C | Co | Ni | |||||

| KF-301 | •APS, HVOF, qoriga qarxinta, wareegsan • Jaakadaha isku xidhka heerkulka sare | |||||||||||

| KF-308 | Nickel Chromium Aluminum Yttrium Alloy | 25 | 11 | 1 | Bal. | HRC 20-30 | ≤ 950ºC | • Duubabka biraha, duub duubka saxanka kulul ee kulul, duubka foornada daaweynta kulaylka. • Garabka injiinka hawada, marawaxadaha gaaska, gaashaanka kulaylka | ||||

| KF-309 | Nickel Cobalt Chromium Aluminum Yttrium Alloy | 25 | 6 | 0.5 | 22 | Bal. | HRC 20-30 | ≤ 950ºC | • Iska caabbinta heerkulka sare, antioxidant. • Iska caabbinta daxalka kulul. • Substrate-ka ka hortagga kulaylka | |||

| KF-336 | Cobalt Chromium Aluminium Silicon Yttrium Alloy | 29 | 7 | 0.5 | 3 | Bal. | HRC 20-30 | ≤ 1000ºC | • Iska caabbinta heerkulka sare, antioxidant. • Iska caabbinta daxalka kulul, substrate | |||

| KF-337 | Cobalt Chromium Aluminum Yttrium Alloy | 23 | 6 | 0.4 | Bal. | 30 | HRC 20-30 | ≤ 1050ºC | • Iska caabbinta heerkulka sare, antioxidant. • Iska caabbinta daxalka kulul, substrate-ka kulaylka | |||

| KF-339 | Cobalt Chromium Aluminum Yttrium Alloy | 24 | 7.5 | 0.8 | 10 | 0.8 | 2 | Bal. | ≤ 1100ºC | •APS, HVOF, qoriga qarxinta, wareegsan • Duubabka biraha, duubka foornada ee heerkulka sare ee nuujinta. • Garabka rotor engine aero, garbaha hagaha iyo marawaxadaha gaaska | ||