Ni-Graphite Cladding budada leh korantada

Sharaxaada

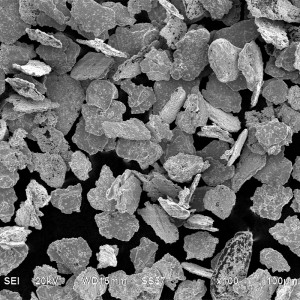

Ni-Graphite Cladding budada waa shay gaar ah oo loo habeeyay si loo bixiyo waxqabad heersare ah oo dalbanaya codsiyada warshadaha.Budada cusubi waxa ay ku xidhan tahay kiimiko ahaan ay ku badan tahay nikkel iyo graphite, taas oo ka dhigaysa doorasho ku haboon in loo isticmaalo xidhashada agabka kombaresarada turbo, daawaha nikkel, iyo qaybaha birta.

Mid ka mid ah sifooyinka muhiimka ah ee Ni-Graphite Cladding budada waa maadada garaafka sare.Sifadani waxay kor u qaadaysaa waxqabadka sifaynta budada, taas oo ka dhigaysa doorasho caan ah oo loo isticmaalo qaybaha titanium-ka ee aan lahayn gees.Intaa waxaa dheer, maadada nikkel ee sare ee budada waxay wanaajisaa iska caabbinta nabaad-guurka, iyada oo hubinaysa inay bixiso waxqabadka ugu fiican ee jawiga warshadaha adag.

Ni-Graphite Cladding budada waxaa lagu heli karaa laba qaab oo kala duwan: KF-21 Ni-Graphite 75/25 iyo KF-22 Ni-Graphite 60/40.Labadan qaab-dhismeed waxay leeyihiin nikkel iyo graphite ka kooban saamiyo kala duwan, taasoo ka dhigaysa inay ku habboon yihiin noocyada kala duwan ee codsiyada warshadaha.Tusaale ahaan, KF-21 Ni-Graphite 75/25 waxay leedahay maaddo nikkel sare ah, taasoo ka dhigaysa mid ku habboon in loo isticmaalo codsiyada u baahan iska caabbinta nabaad-guurka ee sarreeya.

Marka lagu daro sifooyinkeeda waxqabadka sare, Ni-Graphite Cladding budada sidoo kale waa mid aad u badan.Waxaa loo isticmaali karaa noocyo kala duwan oo codsiyada warshadaha, oo ay ku jiraan kombaresarada turbo, daawaha nikel, iyo qaybaha birta.Intaa waxaa dheer, caabbinta ololkeeda iyo heerkulka ugu sarreeya ee 480 ° C ayaa ka dhigaya doorasho lagu kalsoonaan karo oo loo isticmaalo codsiyada heerkulka sare.

Marka ay timaado doorashada saxda ah ee Ni-Graphite Cladding ee codsigaaga warshadaha, waxaa muhiim ah in la tixgeliyo sifooyinka OEM ee qalabkaaga.KF-21 waxay la mid tahay AMPERIT 205, METCO/AMDRY 307NS, PRAXAIR NI-114, iyo PAC 138, halka KF-22 ay la mid tahay AMPERIT 200 iyo Durabrade 2211.

Gebogebadii, Ni-Graphite Cladding budada waa walax aad u khaas ah oo bixisa waxqabad heersare ah oo dalbanaya codsiyada warshadaha.Waxyaabaha ay ka kooban tahay garaafyada sare iyo waxa ku jira nikkel sare ayaa ka dhigaya doorasho ku habboon in loo isticmaalo xidhashada agabka kombaresarada turbo, daawaha nikkel, iyo qaybaha birta.Iyada oo la isku halleyn karo, caabbinta ololka, iyo heerkulka sare ee hawlgalka, Ni-Graphite Cladding budada waa doorasho lagu kalsoonaan karo oo loogu talagalay codsiyada warshadaha kala duwan.

Alaabooyin la mid ah

| Summada | Magaca Alaabta | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-21T/R | Ni-Graphite 75/25 | 205 | 307NS | NI-114 | 138 | |

| KF-22T/R | Ni-Graphite 60/40 | 200 | Durabrade 2211 |

Tilmaamid

| Summada | Magaca Alaabta | Kiimikada (wt%) | Adag | Heerkulka | Guryaha & Codsiga | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤ 800ºC | • Olol, APS, Max.heerkulka shaqaynayo 650°C. • oksaydhation cufan oo mashiin ah u adkaysta oo xidha daahan adkaysi u leh. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤ 800ºC | • Olol, APS, HVOF, Max.heerkulka shaqaynayo 800°C • oksaydhation cufan oo mashiin ah u adkaysta oo xidha daahan adkaysi u leh | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | • Waxa loo isticmaalaa qaybaha xidhidhiyaha guurguura iyo siddo wax lagu xidhi karo •Waxa loo isticmaali karaa sida walxo khilaafaad hooseeya | ||||||||

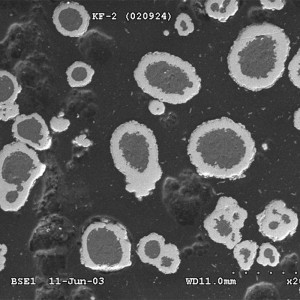

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | • Olol, Max.heerkulka shaqaynta 480°C 1. Xidhashada agabka kombaresarada turbo • Lagu dabaqi karo daawaha nikkel iyo qaybaha birta Alaabooyinka leh garaafyada sare waxay ku habboon yihiin qaybaha titanium oo aan lahayn gees Waxyaabaha garaafyada sare leh waxay kor u qaadi doonaan waxqabadka sifaynta Maadada nikkelku waxay wanaajisaa caabbinta nabaadguurka • Alaabooyinka la midka ah way kala duwan yihiin sababo la xiriira tilmaamo OEM oo kala duwan | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤ 800ºC | • Olol, APS, aan joogto ahayn Waxa loo isticmaali karaa in lagu dhalaaliyo qolof leh, dusha daboolaya ee terminal iyo dusha caaryada sidii lakab ilaalin ah | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | • Olol, APS, aan joogto ahayn • U adkaysiga dubbe, nabaad-guurka, nabar-goynta iyo naaxinta simbiriirixidda | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | • Olol, aan joogto ahayn • U adkaysiga dubbe, nabaad-guurka, nabar-goynta iyo naaxinta simbiriirixidda | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | • Olol, APS, aan joogto ahayn, Max.heerkulka shaqaynayo 815°C. Xiro walxaha dahaarka u adkaysta, kaas oo loo isticmaali karo dayactirka suufka biriiga | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤ 800ºC | • Olol, APS, Max.heerkulka shaqaynayo 980°C. • Plasma oo lagu buufiyo iyada oo isku xidhan | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, aan joogto ahayn, Max.heerkulka shaqaynayo 980°C. •Waxay khusaysaa hagaajinta lakabka isku xidha heerkulka sare ama xidhashada/qaybaha si khaldan loo farsameeyay | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Isku-xidhka, dahaarka adag ee caadiga ah ee codsiga • Adag, oo leh iska caabin daxalka wanaagsan iyo waxqabadka saamaynta • Waxa loo isticmaalaa qaybaha mishiinada, fadhiga iyo galka | |||||||

| KF-31 | Ni-Diatomite 75/25 | • Olol, APS, aan joogto ahayn, Max.heerkulka shaqaynayo 650°C. • Dahaarka shaabadda la shiidi karo, oo ay ku jiraan qaybaha shaabadda la dhaqaajin karo, siddooyin shaabad ah oo la shiidi karo, agabka jajabinta hoose | ||||||||||||